Welcome! This article will show you the door lock manufacturing process and Xhardware Manufacturing.

In the early days, Xhardware Manufacturing primarily produced generic hardware products. Still, the company soon realized that its expertise in design and manufacturing could be applied to create custom hardware that would be popular in the high-end markets of Europe and America. The company’s fast-response designer team was established, and it began offering a wide range of customized products, including door locks, handles, knobs pulls, hinges, and cabinet hardware.

Xhardware Manufacturing’s commitment to quality and attention to detail set it apart in a crowded market. Its products have become popular with importers, brand owners, wholesalers, and distributors worldwide.

I. Door Lock Custom Design Process

Xhardware Manufacturing makes it easy for customers to work with its team of designers to create custom hardware designs that meet their specific needs and preferences.

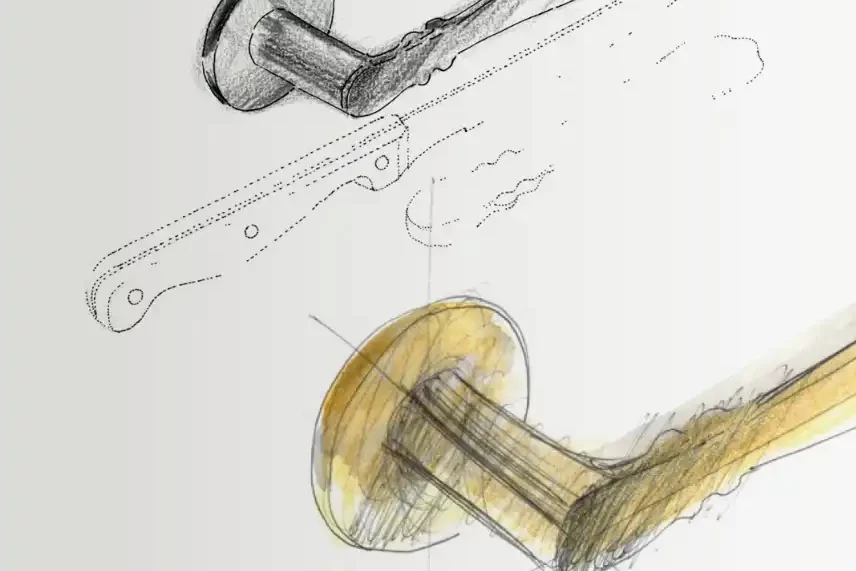

The process begins with an initial consultation, during which the customer discusses their design ideas with the Xhardware Manufacturing team. The company’s designers will work closely with the customer to understand their vision and make recommendations based on their expertise.

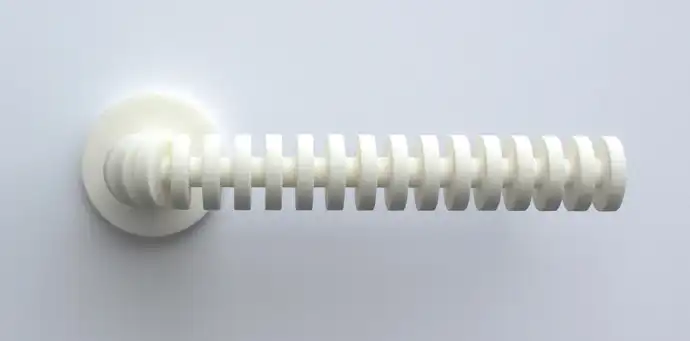

Once the design concept is established, the Xhardware Manufacturing team will create detailed 3D models and prototypes for the customer’s review. The customer can then provide feedback and request changes until the design meets their specifications.

Xhardware Manufacturing’s designers are skilled in various styles, including classic, antique, modern, and simple designs. They have a wealth of experience creating customized products for the high-end markets of Europe and America. This expertise allows them to provide valuable insights and guidance to customers throughout the design process.

Overall, Xhardware Manufacturing’s approach to custom design ensures that customers receive hardware products perfectly tailored to their needs and preferences and meet the highest standards of quality and craftsmanship.

II. Door Lock Manufacturing Process

Xhardware Manufacturing’s door lock manufacturing process involves several steps to ensure that each lock meets the company’s high quality and durability standards.

- Design and Engineering: The first step is to create a detailed design of the lock, including all its components, using 3D modeling software. This design is then sent to the engineering team, who will ensure the wave meets all safety and security standards.

- Raw Material Selection: Once the design is finalized, the team selects the appropriate materials for the lock. Xhardware Manufacturing uses only the highest quality materials, such as brass, stainless steel, and zinc alloy, to ensure the durability and longevity of the lock. Xhardware Manufacturing’s commitment to high-end quality and attention to detail is evident throughout its door lock manufacturing process. The company uses only the finest materials and employs rigorous quality control measures to ensure that each lock meets the highest durability and reliability standards. Brass is one of the primary materials used in manufacturing Xhardware Manufacturing’s door locks. Brass is a highly durable and corrosion-resistant metal that is well-suited for use in door locks. It provides an excellent combination of strength and beauty, making it a popular choice for high-end hardware products. In addition to brass, Xhardware Manufacturing uses stainless steel and zinc alloy in its door locks. These materials are known for their durability and resistance to corrosion, ensuring that the waves will maintain their strength and functionality over time.

- Casting: The selected materials are then cast into the various components of the lock using precision casting machines. This process ensures that each element is of the correct size and shape and that all pieces fit perfectly.

- Machining: After casting, the components are sent to the machining department, refined and honed to precise specifications using advanced machining techniques. The company’s attention to detail is evident in every aspect of the manufacturing process. Each lock is carefully crafted using precision casting and machining techniques, ensuring every component fits together seamlessly and functions smoothly. The waves undergo rigorous testing and inspection to meet Xhardware Manufacturing’s exacting standards.

- Assembly: Once all the components are complete, the lock is assembled by a skilled team of technicians. They carefully fit all the pieces together, ensuring they function smoothly and effectively.

- Quality Control: Before the locks are packaged and shipped to customers, they undergo rigorous quality control measures to ensure they meet Xhardware Manufacturing’s high standards. This includes testing the coils for strength, durability, and reliability.

Overall, Xhardware Manufacturing’s door lock manufacturing process is comprehensive, ensuring that each lock is of the highest quality and meets the company’s exacting standards.

III. China Credit Insurance Corporation

Xhardware Manufacturing is proud to partner with China Credit Insurance Corporation to provide added peace of mind for our customers. This partnership ensures that our importers can be more assured when cooperating with us.

China Credit Insurance Corporation is a state-owned enterprise that provides trade credit insurance services to businesses in China. By partnering with them, Xhardware Manufacturing can offer our customers protection against the risk of non-payment or non-delivery of goods due to factors beyond their control, such as insolvency, bankruptcy, or political unrest.

This partnership benefits our importers in several ways. First, it provides them with an added layer of financial security, reducing the risk of financial loss due to unforeseen circumstances. Second, it enables our customers to expand their business without fear of credit-related risks. This means they can confidently purchase our products, knowing they are protected against potential financial losses.

Xhardware Manufacturing’s partnership with China Credit Insurance Corporation reflects our commitment to transparency and accountability. Building strong relationships with our customers requires us to be open and honest about our business practices and the risks involved in doing business. By working with a trusted partner like China Credit Insurance Corporation, we can offer our customers higher transparency and accountability, ensuring they can trust us to deliver on our promises.

Our cooperation with China Credit Insurance Corporation is just one example of our commitment to providing our customers with the best possible experience. We are always looking for ways to improve our processes and services, and we believe this partnership is an essential step in that direction.

IV. Conclusion

In summary, Xhardware Manufacturing is a leading manufacturer of decorative hardware, offering a wide range of custom designs and high-end quality products that are loved by European and American high-end markets. Our commitment to using the finest materials, employing the most advanced manufacturing techniques, and employing rigorous quality control measures ensures that every product we produce meets the highest durability and reliability standards.

We take pride in our ability to work closely with our customers to create custom designs that meet their specific needs and preferences. Our fast-response designer team is experienced in creating classic, antique, modern, and simple styles loved by high-end markets. And with our commitment to using environmentally friendly packaging, our customers can be assured that we are doing our part to reduce our impact on the planet.

As importers, brand owners, wholesalers, and distributors consider their decorative hardware needs, we invite them to consider Xhardware Manufacturing as their partner of choice. Our reputation for excellence in design, quality, and customer service makes us a trusted partner for businesses worldwide. And with our partnership with China Credit Insurance Corporation, our customers can be confident that they are working with a company committed to transparency, accountability, and the highest standards of ethical business practices.

We look forward to working with you and demonstrating our commitment to providing the best possible products and services. Please don’t hesitate to contact us to learn how we can meet your decorative hardware needs.